The Linx Safe gasketed systems lead the industry in assembly times, leakage rates, and aesthetics. Forget about painting sealants on these joints, and don’t even think about wrapping this system!

What is the Linx Safe Duct Connection System?

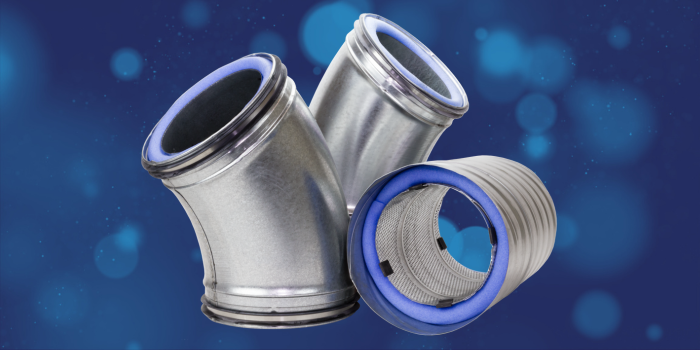

Linx Safe is a complete line of self-sealing spiral ductwork and fittings based on a U-profile, EPDM rubber gasket. This gasket is located in the groove at the end of the fitting and is securely attached by a stainless-steel band, ensuring that the rubber gasket is always held in the correct position.

When a fitting is inserted into the spiral duct, the gasket folds back, forming a seal against the inside and eliminating the need for duct sealant. As shown below, various gasket sizes are used to achieve optimum sealing for all diameters.

The standard Linx Safe gasket is made from a material resistant to ozone, UV rays, and temperature fluctuations and is rated for temperatures from -20° F to +212° F. A silicone gasket for special applications is also available, rated for temperatures from -94° F to +302° F.

The Linx Safe duct system also offers the following benefits:

- Factory-installed gasket (no loose parts)

- Fast and easy installation

- Environmentally friendly, no harmful sealants required

- Installation not contingent on weather

- Double-lipped gasket minimizes the risk of leakage in the event of damage

- Meets SMACNA’s Leakage Class 3

- Gasket UL classified rating (Flame spread – 0 / Smoke developed – 0) by ASTM standard E84 and ANSI / UL 723

- Rolled over edges for easier installation, reduces the risk of injury and adds strength

- Adjustability – fittings can be rotated 360° during installation and still maintain the seal’s integrity

Superior Installation Quality, Cost, and Time Savings with Linx Safe

With the Linx Safe System, regardless of whether you choose a single- or double-wall round system, you can count on superior installation quality, cost, and time savings. Material cost for Linx Safe with a gasket is approximately 15-20% less expensive than factory-installed double-face flanges. In addition, installation time is approximately 10-40% more efficient with the single slip fit vs. flanging for a variety of reasons, including:

- If flanges are not installed square to the pipe and fittings, the ductwork will not be visually straight.

- A slip-fit connection allows minor adjustments to the ductwork alignment to accommodate offsets.

- If a field cut is required on flanged ductwork, either a slip fit and sealed connection will result, or the contractor will need to order additional flanges to be field installed. Removing already installed and sealed flanges is difficult, particularly if they were tack welded to the ductwork.

- Flanged connections require the contractor to furnish and install a gasket between the mating flanges.

- A flanged connection requires more mechanical fasteners than the Linx Safe connection.

- For field-installed flanges, the contractor must attach and seal each flange to the ductwork.

- There is no testing or long-term documentation for the performance of duct sealing mastic materials to prevent duct leakage.

Where Can I Buy the Linx Safe Duct System?

Ready to buy the Linx Safe System? As always, we want you to ask for Linx and are happy to work with you to deliver your desired HVAC products.

Available in both single-wall and double-wall, the complete Linx Safe System with ductwork and fittings can be purchased through over 60 representative locations across the US as part of our selective distribution network. Use the Linx representative locator map to find a rep near you and place your order today!